{australien_flagge} The liquefied natural gas industry in Queensland, Australia, is young and extremely successful, but it has a stubborn wastewater problem. Outside of Australia, the scale of this industry may be known to few. By liquefying coal seam gas, Queensland serves about 6% of global LNG demand. It is estimated that major energy companies have invested no less than A$80 billion in Queensland since the 2010s. In 2022 alone, the three LNG hubs at the Port of Gladstone generated some A$25 billion in revenues.

Conclusion: with its current market capitalization of just A$26 million, Parkway is a featherweight compared to the caliber of its potential gas industry customers. Nevertheless, Parkway has the confidence to build, own and operate at least the simpler upstream brine concentration facilities – possibly with one or more partners, depending on project-specific parameters. One possible commercialization strategy is to license the technology and receive a royalty for its use. Another option is to pool financially strong investors in the wholly owned subsidiary “Queensland Brine Solutions” (QBS). Capital dilution would then occur at the subsidiary level rather than at the listed company level. In either case, Parkway would likely need to raise minimal equity for its projects, despite the opportunity to build a potentially significant business. We note from a recently released independent research report, there is significant upside to the valuation of Parkway, even based on moderate success.

The liquefied natural gas industry in Queensland, Australia, is young and extremely successful, but it has a stubborn wastewater problem. Outside of Australia, the scale of this industry may be known to few. By liquefying coal seam gas, Queensland serves about 6% of global LNG demand. It is estimated that major energy companies have invested no less than A$80 billion in Queensland since the 2010s. In 2022 alone, the three LNG hubs at the Port of Gladstone generated some A$25 billion in revenues.

But this industry success has an environmentally damaging downside. The water produced during coal seam gas production results in waste brine, the disposal of which has not yet been able to be achieved. The Queensland government is demanding a sustainable solution in accordance with the Best Available Technology (BAT) by in the near term. On top of that, the companies themselves have an urgent interest in solving the problem. First, they want to continue producing at the Queensland site and expand production, and second, there are other huge undeveloped coal seam gas systems in Australia whose permitting would greatly benefit from a satisfactory solution to the Queensland wastewater problem.

Queensland gas producers have by no means been idle in the past. It is estimated that the CSG industry in Queensland has invested more than $100 million in attempting to solve the residual brine problem over the past decade. Nevertheless, the industry has not yet progressed beyond an interim storage option. The residual brine is currently stored temporarily in above-ground ponds. Again, one must consider the dimensions: Shell subsidiary QGC is a pioneer in the treatment of residual brine. The company invested one billion AUD for two large plants for salt concentration. The two QGC plants are operated by Veolia. The associated service contracts are worth AUD 800 million and run for 20 years. These costs would have undoubtedly escalated in the decade since the contracts were awarded. However, even with this costly process, the residual brines remain in concentrated form, and still require a further investment, in the form of mixed salt crystallizers. Therefore, it is officially evaluating options to convert the brines into salts, another costly exercise, and permanently encapsulate the residual solids into landfill. For now, this concept is still considered Best Available Technology (BAT), but one can understand why the industry has been reluctant to implement it, given the perpetuity costs of landfilling. Further, unsurprisingly, no such facilities have been approved for construction, given the many risks and challenges.

In the end, however, CSG companies are required to treat their waste and produce recyclable products – disposal is only an option if that recycling is not possible. Experts have projected that Queensland’s gas production facilities will accumulate about 6 million tons of problematic salt over their lifetime in the coming decades. The total potential cost of treating current and future brine production is estimated to be in the order of A$21 billion – this figure includes up to A$4 billion for solids disposal and storage alone.

Parkway raises the bar for Best Available Technology (BAT)

That’s where the proprietary process technology of Australian cleantech company Parkway Corporate Limited (ASX: PWN; FRA: 4IP) comes in. By effectively treating brines from Queensland’s gas fields, Parkway promises not only to solve the environmental problem, but to turn nearly 100% of the wastewater into usable products. Parkway’s technology potentially offers a significant cost advantage over the base case of brine encapsulation, which should make it attractive to both the regulator, as well as gas producers.

The technology for processing residual waste brines with Parkway’s technology, was recently validated by a successful feasibility study commissioned and funded by one of the major CSG LNG operators. This involved the successful treatment of brine samples using Parkway’s technology portfolio, including the Integrated Brine Bacteria Classification (“iBC®”) process. The study was conducted in collaboration with major engineering firm Worley (WOR: ASX) and Victoria University. Parkway’s process could establish itself as the new “Best Available Technology.” The new solution is enticing energy companies with the prospect of even turning their problematic residual brines into a profit center in the long run by selling salt-based end products. Parkway’s proprietary and patented processes produce pure water and saleable end products such as sodium hydroxide, lime and industrial salt, with less than 2% of the treated material requiring disposal. Including product sales (estimated by the company to be about $2.5 billion), there is a potential savings of more than $17 billion over salt encapsulation, which should make the project attractive to industry.

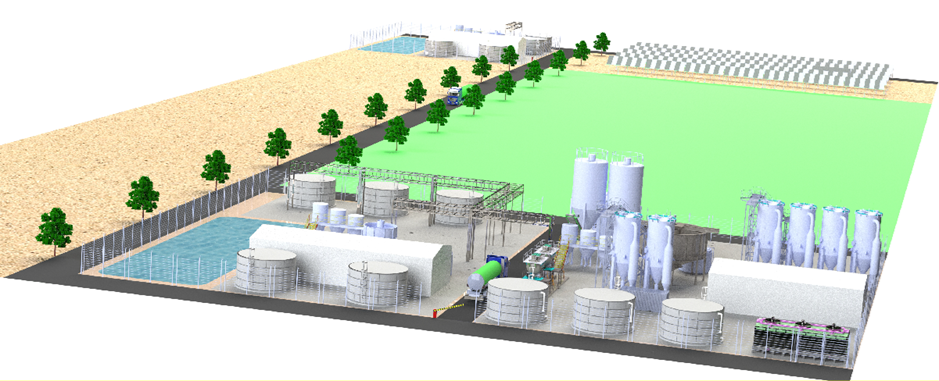

Figure 1: Schematic diagram of a combined plant for the concentration of residual brine and the subsequent extraction of end products. The two parts can also operate spatially separately, opening up the vision of decentralized concentration plants in conjunction with centralized downstream hubs.

Master plan provides basis for discussion for all stakeholders

Parkway recently released a comprehensive master plan detailing the commercialization of the project in Queensland. The document is designed to initiate formalized discussions with all stakeholders: Energy companies, government agencies, industry, including end-users of the products. Judging by the preliminary coverage Australian media have devoted to the issue of residual waste brines, this discussion is likely to receive wide media coverage.

While the option outlined above is being evaluated by the customer, Parkway is moving forward with the potential implementation of an upstream brine concentration and treatment process that would provide significant benefits to the remaining three major CSG projects in Queensland in the near future. In particular, a smaller and less expensive brine storage facility. The upstream concentration and treatment of wastewater brine would also allow further processing of brine with Parkway’s downstream process technologies at a later date, depending on project-specific requirements.

Parkway has indicated we can expect more news on this front in the near future.

Standard modular plant design for rapid solutions

In order to quickly provide a viable solution to the CSG industry in Queensland, Parkway is currently developing standard designs with modular plants based on Parkway’s proprietary brine concentration and treatment process. Preliminary internal assessments indicate that Parkway is likely to be able to offer CSG companies a highly attractive brine concentration service (lower cost, better outcome) on a toll-treatment basis.

The potential of Parkway’s technologies extends well beyond Queensland. Globally, potential applications include treatment of mine and energy wastewater or municipal wastewater and desalination residuals. In addition to near-term opportunities related to the CSG sector in Queensland, Parkway has already been approached about several additional opportunities since the release of the master plan, including a greenfield project in another part of Australia and a potential application in an established gas production area in North America. We understand, this is in addition to opportunities previously disclosed in the Middle East.

Stable growth in operating business

Parkway also runs an operating business, Parkway Process Solutions (“PPS”), a conventional water treatment company that provides equipment, services and integrated solutions. Although still quite small, with revenues of A$4.69 million in the last 12 months (compared to A$2.32 in the previous period) and a healthy EBITDA margin of approximately 40%, the business has grown rapidly through internal growth and acquisitions in its two years of existence. Despite ongoing investments in technology, plant and equipment, the cash position for the company is stable. The quarterly report for the end of June 2023 shows strong quarterly sales with revenues of $1.09 million for the period. Cash receipts from operations increased to a record $1.32 million. As of June 30, 2023, the company had cash reserves of $2.05 million. Consolidated revenues are supported by a large project backlog (>$1 million in open orders).

Conclusion: with its current market capitalization of just A$26 million, Parkway is a featherweight compared to the caliber of its potential gas industry customers. Nevertheless, Parkway has the confidence to build, own and operate at least the simpler upstream brine concentration facilities – possibly with one or more partners, depending on project-specific parameters. One possible commercialization strategy is to license the technology and receive a royalty for its use. Another option is to pool financially strong investors in the wholly owned subsidiary “Queensland Brine Solutions” (QBS). Capital dilution would then occur at the subsidiary level rather than at the listed company level. In either case, Parkway would likely need to raise minimal equity for its projects, despite the opportunity to build a potentially significant business. We note from a recently released independent research report, there is significant upside to the valuation of Parkway, even based on moderate success.

We look forward to the upcoming discussions with the industry and the government, and expect news on a number of milestones that have the potential to be important valuation related catalysts.

Disclaimer: GOLDINVEST Consulting GmbH offers editors, agencies and companies the possibility to publish comments, analyses and news on http://www.goldinvest.de. These contents serve exclusively the information of the readers and do not represent any kind of call to action, neither explicitly nor implicitly they are to be understood as an assurance of possible price developments. Furthermore, they in no way replace an individual expert investment advice, it is rather promotional / journalistic publications. Readers who make investment decisions or carry out transactions on the basis of the information provided here do so entirely at their own risk. The acquisition of securities involves high risks, which can lead to a total loss of the invested capital. The GOLDINVEST Consulting GmbH and its authors exclude any liability for financial losses or the contentwise warranty for topicality, correctness, adequacy and completeness of the articles offered here expressly. Please also note our terms of use.

According to §34b WpHG and according to paragraph 48f paragraph 5 BörseG (Austria) we would like to point out that principals, partners, authors and employees of GOLDINVEST Consulting GmbH hold or may hold shares of Parkway Minerals and therefore a possible conflict of interest exists. We cannot exclude that other stock letters, media or research firms discuss the stocks we recommend during the same period. Therefore, symmetrical information and opinion generation is likely to occur during this period. Furthermore, there is a consulting or other service contract between Parkway Minerals and GOLDINVEST Consulting GmbH, with which a conflict of interest exists, since this contract includes that Parkway Minerals remunerates GOLDINVEST Consulting GmbH for the preparation of reports on Parkway Minerals.